Containerized, mobile and modular drinking water purifying system for rural areas to treat the existing but contaminated water easily and cost-effectively. PurAID® is a sustainable tailor-made water supply system for rural, isolated or less accessible areas and at institutions (hospitals, hotels, schools, etc.). The solution is certified by the United Nations and is listed by the UN among the SDG Acceleration Action tools.

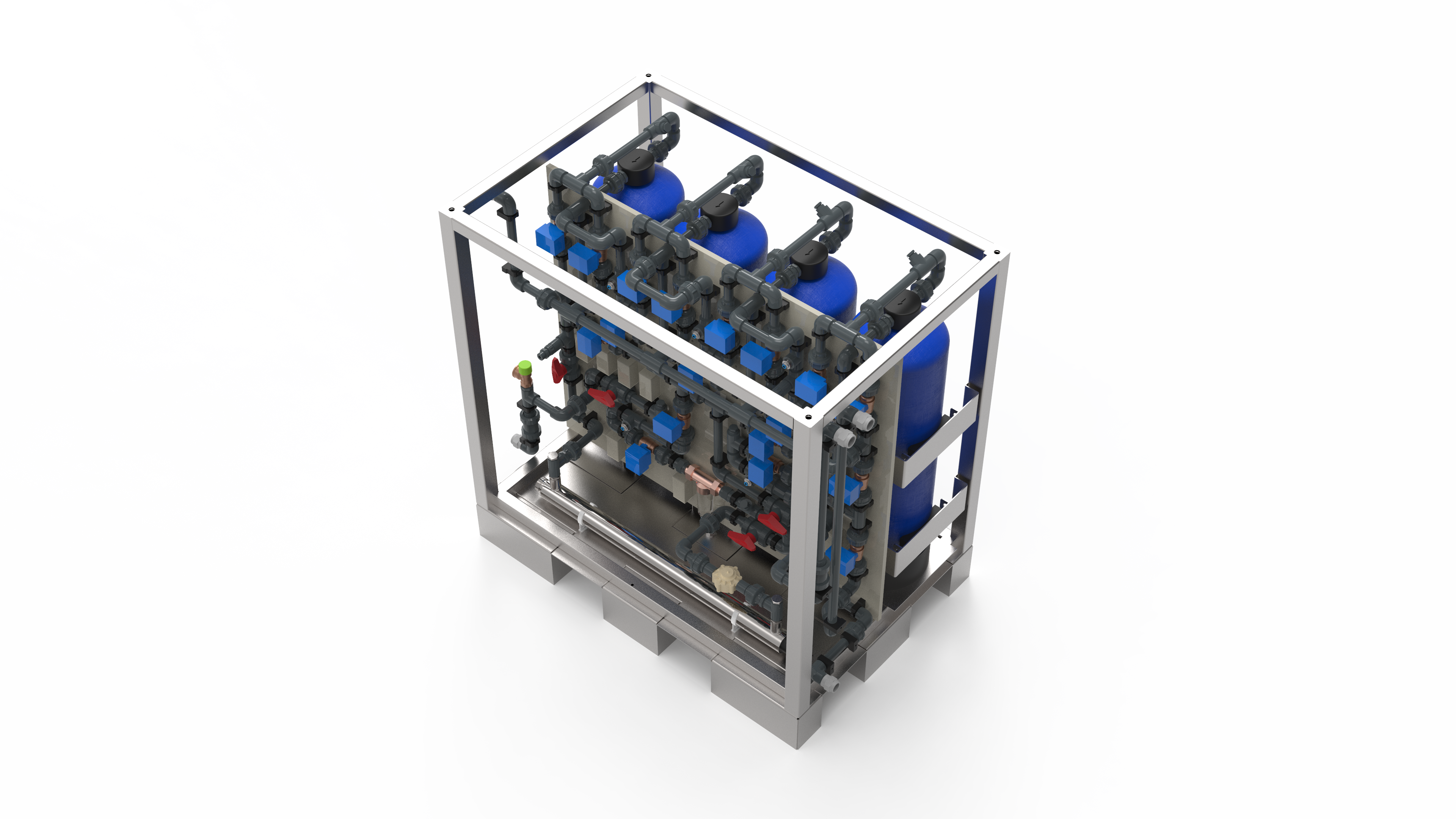

PurAID® system provides a complete solution to remove iron, manganese, ammonia, arsenic, boron and iodine and infections from drinking water in five steps. Depending on the water's contamination, PurAID® can provide more tailor-made assistance.

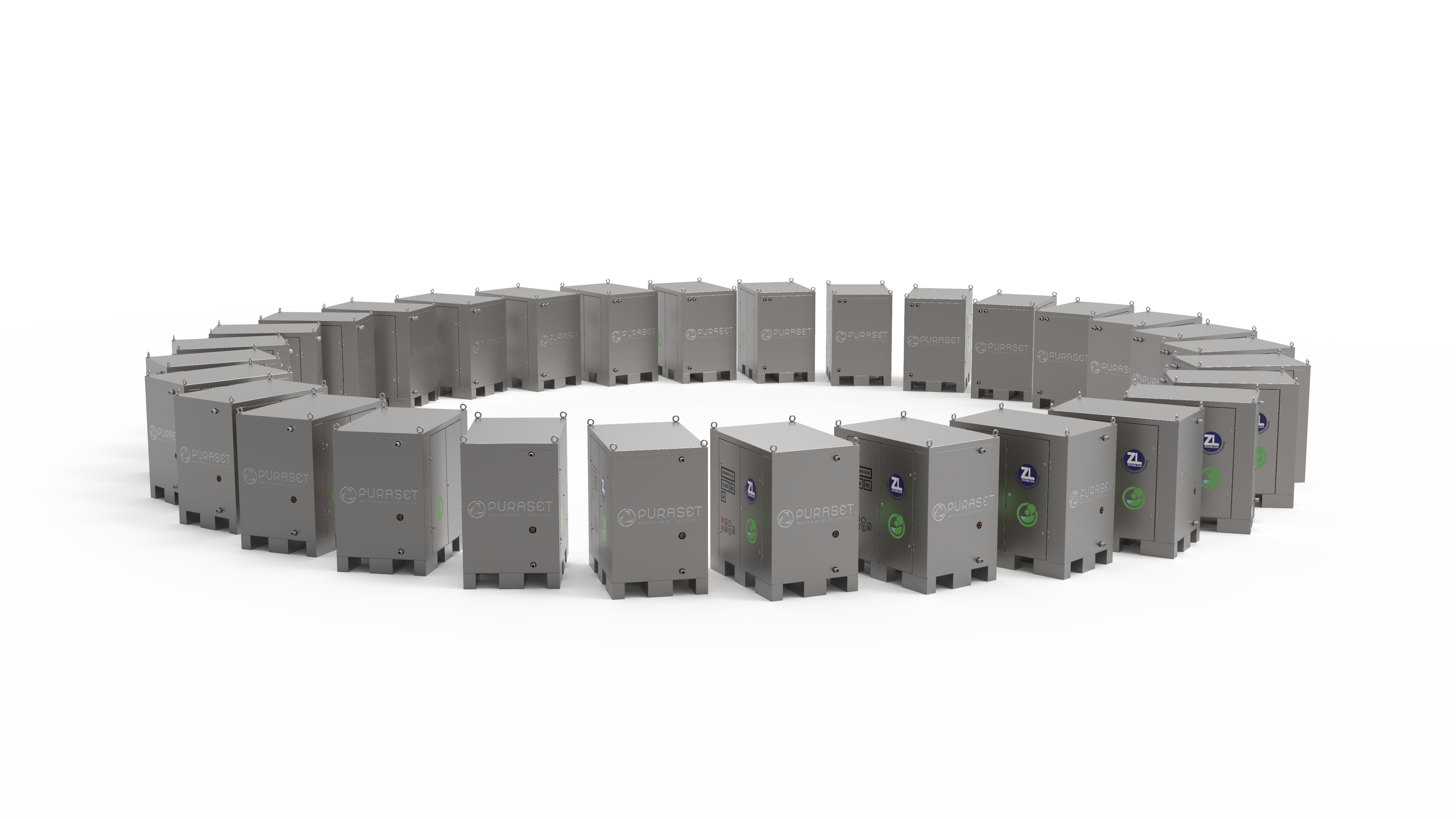

The PurAID® units can easily be organized into a network by connecting 5-10 individual units into a complex system, and installing a Service and Monitoring Center. PurAID® units are installed in a pallet-sized uniform metal box. Each box is equipped with a communication device to transmit the data measured by the modules' sensors. It works via GPS to the Service and Monitoring Center. Regeneration and changing of the filter media and adsorbent materials are also performed in the Center.

- Capacity 100-6,000 l/ day

- requires little space

- only water flow is needed for operation

- provides clean potable water

- removes arsenic materials

Field of application

- household level to community level

Advantages of the product

- provides clean, potable water from

- contaminated drinking water

- designed to use in rural areas and fit local needs

- design allows fitting the energy supply to the local conditions:

- solar panel or AC input

- easy to match the technology to local water

- sources having different water qualities

- can be joined to existing tube-wells

- easy to adopt to other solutions

- sustainable and environment-friendly solution

- no needed to store water

Key benefits

- simple to use conveniently for women or children to use the system

- flow-through system for ongoing water supply if it is necessary

- simple maintenance: the system does not require continuous operator control

- simple to fit different water source and existing water treatment technologies

- it does not change the smell, taste and colour of the water

- the compact, one container system blocks the contamination of the parts, mainly the filters and adsorbent

- the life cycle of the arsenic or boron adsorbent is a minimum of 7 years and the waste adsorbent is not a hazardous material,

Technical data

- smallest equipment contains 25 liters of adsorbent material

- capacity of 250 liters / hour, 6m3/day

- flow-through system for ongoing water supply if it is necessary

- the waste adsorbent is not hazardous material

- UV lamp needs to be changed in every two years