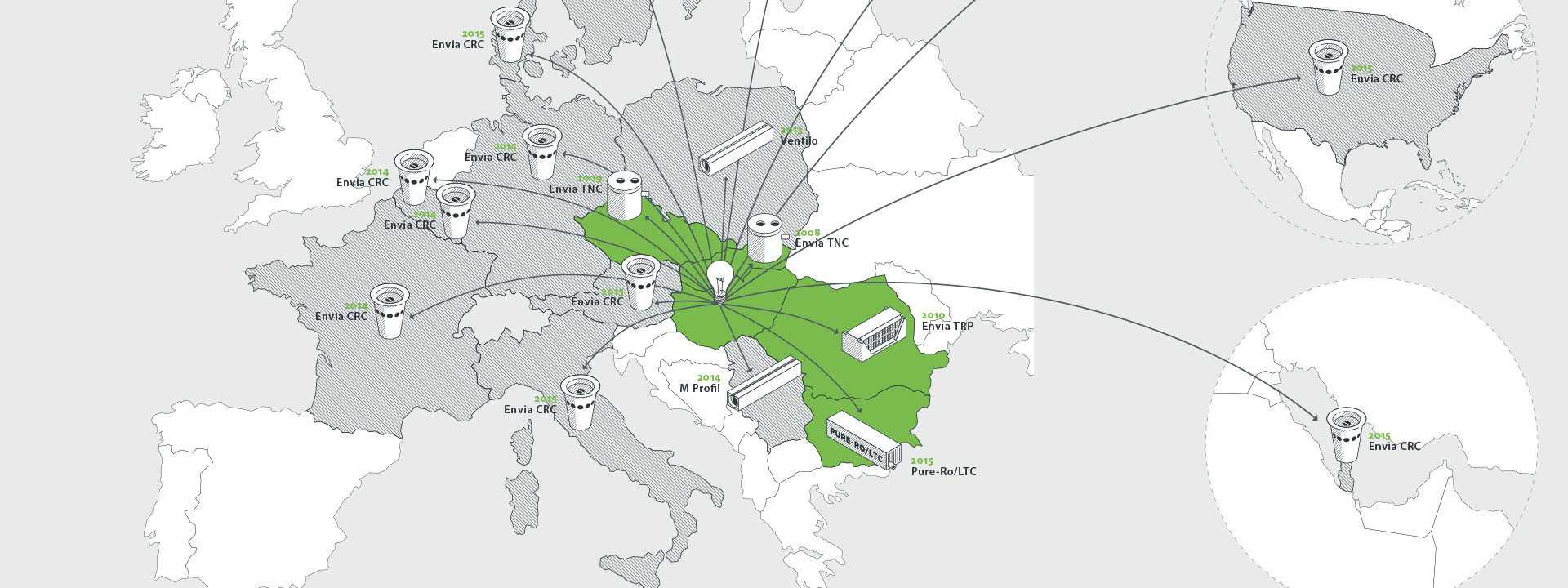

The components of galvanized steel structures have been used for construction in civil engineering for over 100 years. The first application of this type of construction took place in North America and Russia, where the idea of using them in road and rail construction was born. Today, buried flexible steel structures are widely used in construction around the world. Structures of this type, due to the nature of their work, are often referred to as flexible structures. Soil-steel interaction means that a flexible steel structure acts with the surrounding soil fill to support the loads. They are cheap, easy and quick to build. The average installation time with a few people brigade takes a few days. MultiPlate MP200 production process involves the mechanical shaping of flat steel plates into corrugated curved plates which are later hot-dip galvanized. The finished corrugated plates can also be epoxy painted on request. All of the manufacturing takes place in a quality- controlled factory process. The selection of plate thickness depends on the structure’s shape, span, depth of cover and live load. Please take the opportunity to consult with ViaCon’s Technical Department for advice and assistance and your project.

Bolts, nuts, anchor bolts:

Corrugated steel plates are joined with M20 bolts class 8.8. The lengths of the bolts are related to thickness of connected plates and type of connection. There are two types of bolt heads – oval-shaped and cone-shaped with dimensions: 32 mm, 37 mm, 45 mm, 50 mm, 70 mm. The bolt diameter of 20 mm and associated nuts correspond to the requirements norm of EN ISO 898-1 EN 20898-2. Anchor bolts casted into concrete with a diameter of 20 mm and length of 225 mm or 365 mm which are cast into concrete are made of steel conforming the requirements of EN ISO 898-1 & EN 20898-2. All of the ancillary items mentioned above are delivered together with corrugated plates as a complete package for the structure.

Corrosion protection:

Coatings applied by immersion including hot-dip galvanizing provide a durable method of corrosion protection to steel surfaces. The protection is particularly effective due to the intimate and lasting bond between the galvanizing coating and the steel surface, thereby providing extended service life. MultiPlate MP200 structures are protected by hot galvanizing as standard, with zinc coating layer according to EN ISO 1461.

- assembly possible in temperatures below zero

- assembly possible with no traffic interruptions

- assembly possible with total or partial prefabrication of the structures

- corrugated steel plates Are easily and economically Delivered to remote location

Fields of application

- road and rail construction

Advantages of the product

- cheap, easy and quick to build

- quality controlled manufacturing

- light weight

- FAST AND EASY ASSEMBLY

Technical data:

- two types of bolt heads – oval-shaped and cone-shaped

- bolt diameter of 20 mm and nuts of EN ISO 898-1 EN 20898-2

- complete package: bolt, nuts and plates

- steel used for production of MultiPlate MP200 conforms to EN 10025 and EN 10149

- steel grade: S235JR, S355J2 or S355MC

- yield strength for this steel is 235 MPa and 355 MPa.

- MultiPlate MP200 has a CE Certificate of Factory Production Control No. 1023-CPR-0640F.

Key Benefits

- simple design due to standard drawings and a calculations database for standard applications

- fast and easy assembly

- light weight, the corrugated steel plates can be delivered easily and economically to remote locations

- reduction in the total time and cost of construction